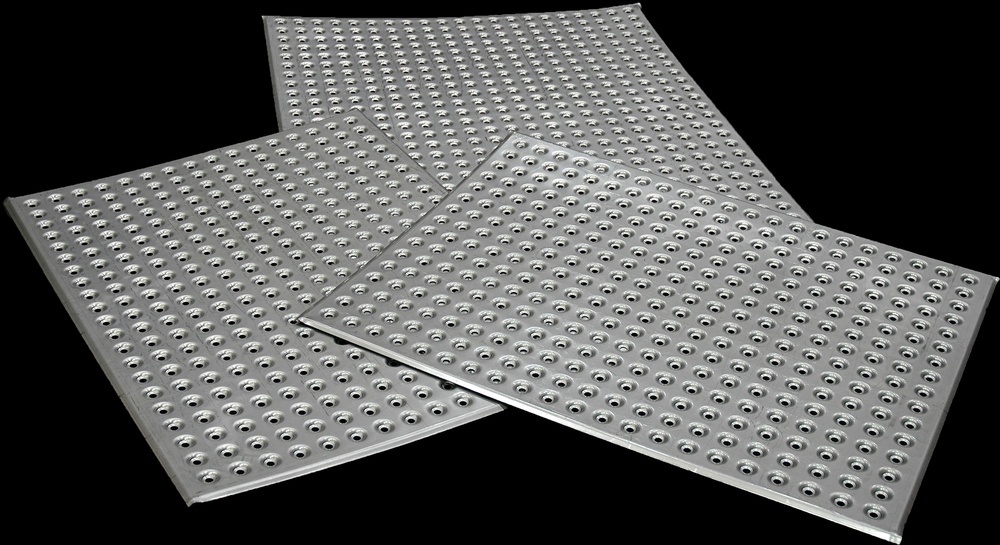

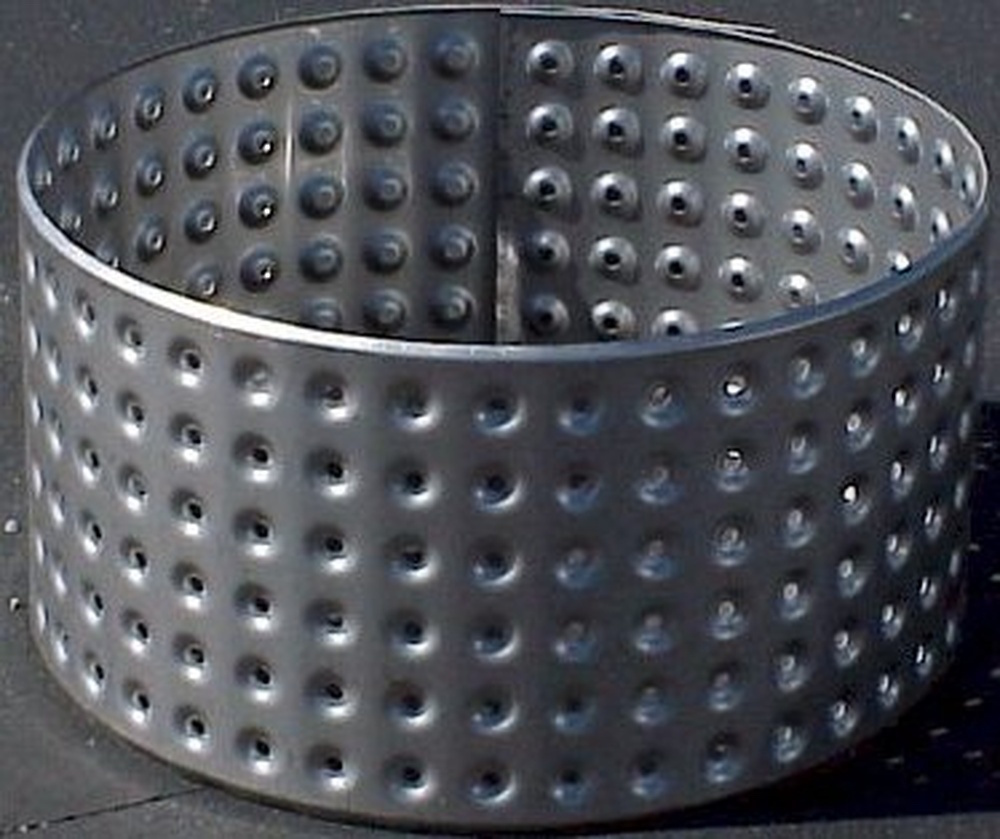

Dimple Heat Transfer Shells

Use Our Dimple Heat Transfer Surfaces with All Your ASME Code Vessel Heating or Cooling Systems.

Overall Heat Transfer Surface. Extended Tank Life.

You want your vessel to provide years of carefree service. Well, so do we. That’s why we offer stainless steel dimple heat transfer surface shells that provide effective overall heat transfer for your process, increasing the allowable working pressure in the vessel as well as extend the working life of the equipment. Proven materials of construction are used in our heat transfer including 304L, 316L, some Super Duplexes, all in 14-gauge and 12-gauge thicknesses.

HOLLOWAY AMERICA offers heat transfer surfaces welded to cylinders and shells along with ASME code stamping, if required. Other available technical options include crimped edges for easier welding, multiple spot spacing options, with shells provided in the flat or rolled position.

Table 1—Pressure Chart

| Dimpled Material | Backing Material | Maximum Allowable Working Pressure | ||||

|---|---|---|---|---|---|---|

| 100° | 200° | 300° | 400° | 500° | ||

| 14 Ga / 316/316L | 12 Ga & Greater / 304L | 260 | 260 | 260 | 246 | 229 |

| 14 Ga / 316/316L | 12 Ga & Greater / 316L | 260 | 260 | 260 | 244 | 230 |

Contact HOLLOWAY to discuss your specific heat transfer surface needs.

Dimple Heat Transfer Surface Options

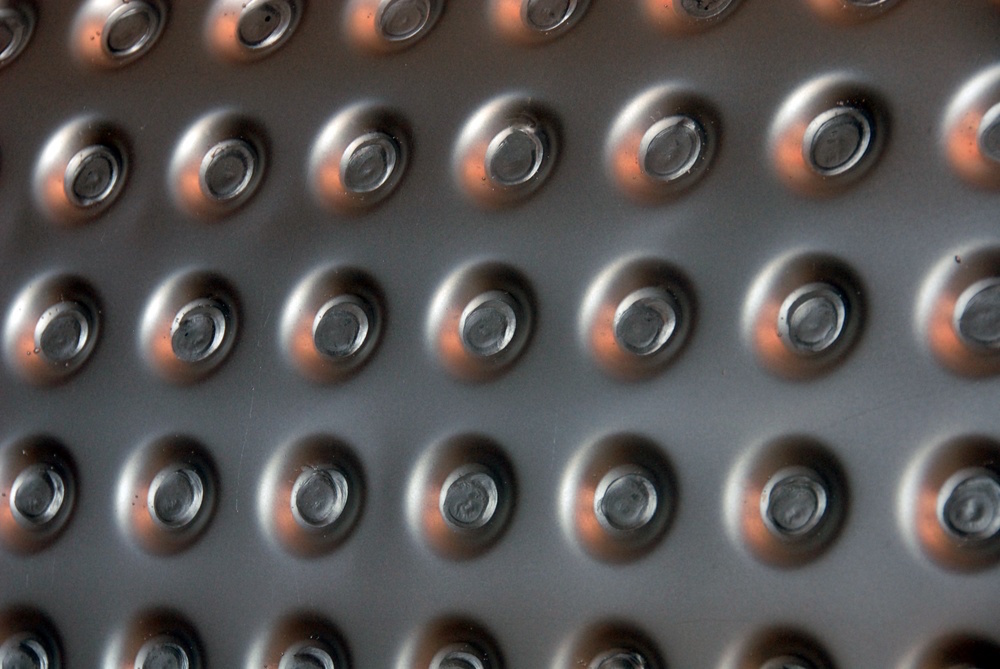

For better maximum allowable working pressure, we provide overall heat transfer surfaces with the following options:

- 1/2" hole & 1/4" pillow height

- 2" x 2", 2–1/2" x 2–1/2", 3" x 3", or 4" x 4" spot spacing

- In the flat or rolled

- Edges crimped down for easier fitup & welding

- Dimple overall heat transfer surfaces welded to cylinder and ASME Code stamped