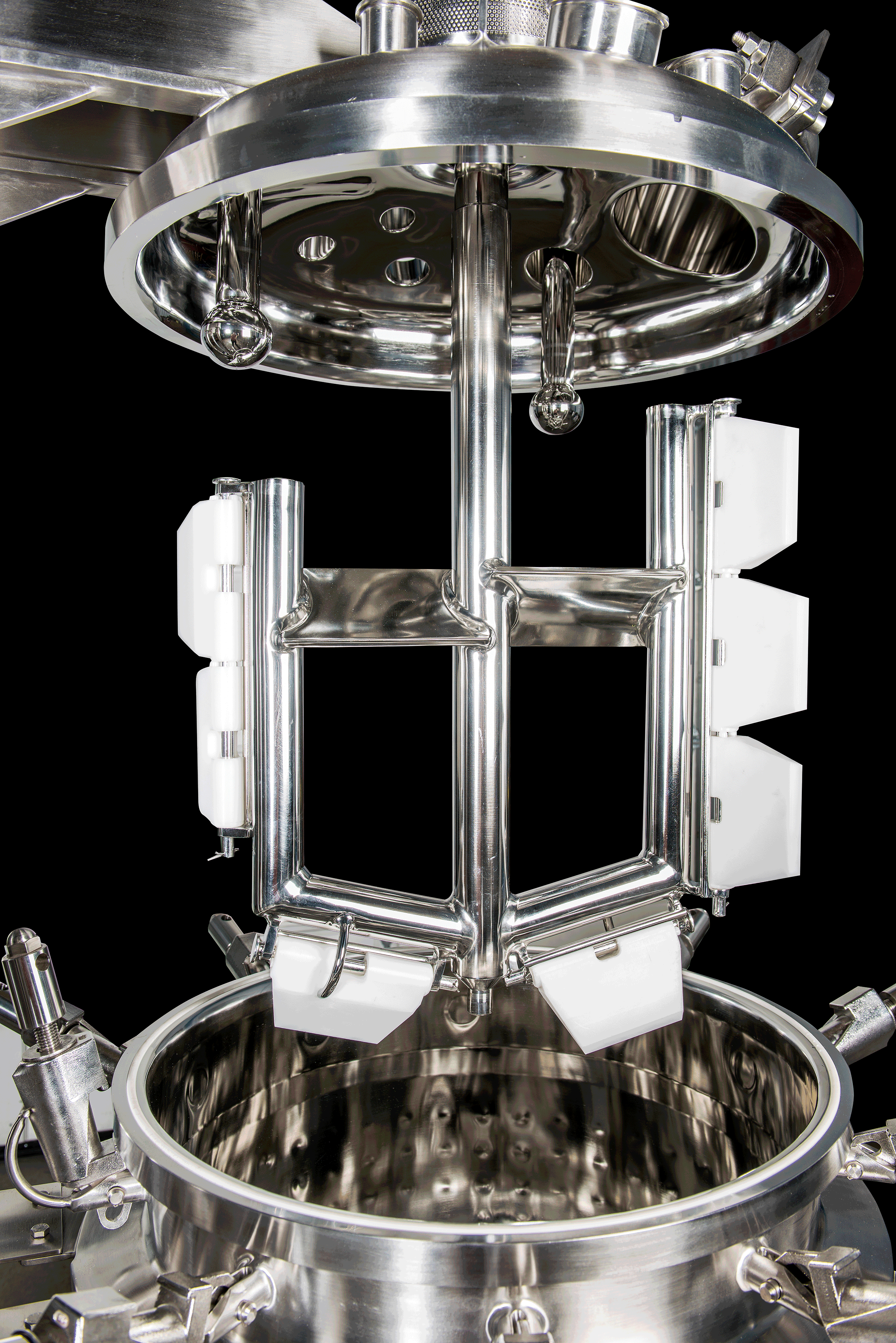

Mixing Tanks & Vessels

At HOLLOWAY AMERICA, we proudly craft and engineer mixing tanks and mixing vessels that blend consistently to help increase your production output and maintain product quality.

Better product. Better performance. This is mixing tank fabrication at its finest.

HOLLOWAY AMERICA is proud to be a mixing tank fabricator for industries ranging from pharmaceutical to food and dairy to beverage. When you need a mix tank that efficiently mixes powder, suspends solids, agitates low or high shear, or gently stir your products, we'll be there to assist you in your planning and estimating requirements. We can fabricate your mixing vessel in a wide variety of sizes—from one liter to 30,000 liters, under pressure or in atmospheric conditions. Send us your requirements and let us help you with one of the things we do best—designing and fabricating quality mixing tanks and vessels.

Mixing Tank Considerations

When selecting your mixing tank or mixing vessel, keep these things in mind:

- Single-wall or heating-jacket requirements

- Insulated with a stainless steel outer sheathing

- Top-entering mixer or bottom-entering mixer with magnetic coupling

- Stationary or portable vessel design

- Pressurized or atmospheric design

- Food-grade or Pharmaceutical-grade finish requirements

Ready to have a conversation about your project?

So are we. Talk to one of our representatives to get started.

Talk to a Rep

Size and Materials of Construction

We craft ASME vessels from 6" diameter up to 144" diameter and test each and every vessel to meet stainless steel ASME code requirements. We are capable of construction using almost any 300 Series Stainless Steel material as well as most High Nickel Alloys.

Whether your process demands an ASME mixer tank, bioreactor, or any of our other ASME stainless steel pressure vessels, our available surface finish regimen covers a broad range. From Mill plate to Standard Grit finish offerings, all the way to low mechanical 5Ra to 10Ra range, all our surface finishes can be complemented by our in-house H-Electropolish™ service.

Our ASME Stamps

HOLLOWAY AMERICA holds both ASME “U” and National Board “R” stamps. Below are a few of the stainless steel ASME codes and standards we meet:

- ASME Section VIII, Division I “U”

- ASME BPE

- CE / PED (Conformité Européenne, meaning "European Conformity”) / Pressure Equipment Directive

- CRN (Canadian Registration Number)

- NR-13

- MOM (Ministry of Manpower)

All welders at HOLLOWAY AMERICA are certified to ASME Section IX.

ASME Pressure Vessel Materials

To ensure the ASME pressure vessels we engineer perform to perfection and are built to last, we use only excellent stainless materials:

- T–316L (standard)

- T–304L

- T–317L

- C–22

- C-276/HASTELLOY®*

- AL-6XN®*

- Other materials available by request

*HASTELLOY® is a trademark of Hanes International, Inc. and AL-6XN® is a trademark of Allegheny Ludlum.